Researchers at University of Bologna and Electrolux have recently developed a new robotic system that could assist humans with one of their most common everyday chores, doing laundry.

This system, introduced in a paper published in SpringerLink’s Human-Friendly Robotics, was successfully trained to insert items and pick them up from the washing machine once a washing cycle is complete.

“Our recent project is the result of a collaboration between an industry partner Electrolux and the University of Bologna,” Gianluca Palli, one of the researchers who carried out the study, told TechXplore.

“There was interest from our industry partner, Electrolux, to develop and deploy robotized laundry manipulation into their domestic appliance test laboratory, to speed the test and evaluation of new products. This interest is motivated by the fact that deploying robotic systems could potentially benefit them in saving time and money, by operating test and validation 24/7 with minimal to no human intervention.”

The University of Bologna’s Laboratory of Automation and Robotics (LAR) has been conducting extensive research focusing on robotic manipulation. Over the past few years, researchers at this lab introduced numerous promising systems, including robotic hand design and novel methodologies for switchgear wiring and manipulation of deformable objects.

“This matching interest between Electrolux and our lab led to a collaboration that officially launched in 2017,” Palli said. “The main objective of this collaborative project, including our recent paper, was to develop and evaluate a robotic system (perception pipeline and control algorithms) to automate laundry operations.”

The goal of recent research efforts by LAR and Electrolux is to eventually replace human operators at laundry cleaning stores and services with fully autonomous mobile robotic arms. This is far from an easy task, as clothes are highly deformable, and robots typically struggle to efficiently handle deformable objects.

For a robotic system, doing laundry entails several steps. These steps include detecting clothes that need to be washed, picking them up, inserting them into the washing machine, interpreting the information on the washing machine’s display and adjusting the settings on the machine to perform the desired washing cycle.

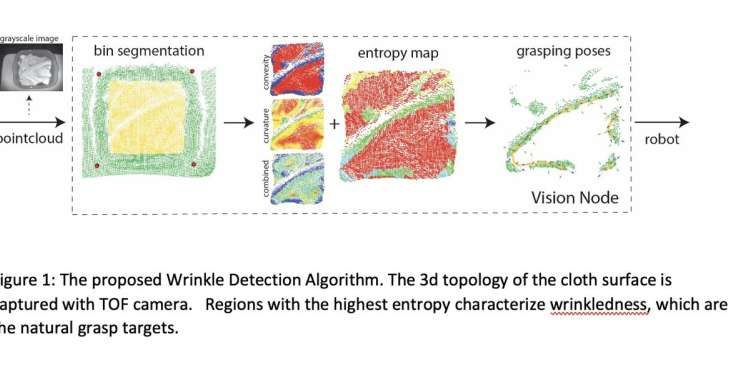

To improve their robotic system’s ability to grasp and manipulate items of clothing and other textile items, the researchers developed a pointcloud-based perception algorithm. This algorithm can detect wrinkles on a cloth-based surface, compute spline curves along the wrinkle-like structure, and estimate optimal grasping frames.

“To improve the graspability of objects in the absence of wrinkles, we also evaluated a blob detection approach together with grasp pose quality ranking, which identifies optimal poses,” Palli said. “We also developed a deep learning-based washing machine user interface detection and interpretation algorithm, which allows us to fully automate the robotic laundry operation.”

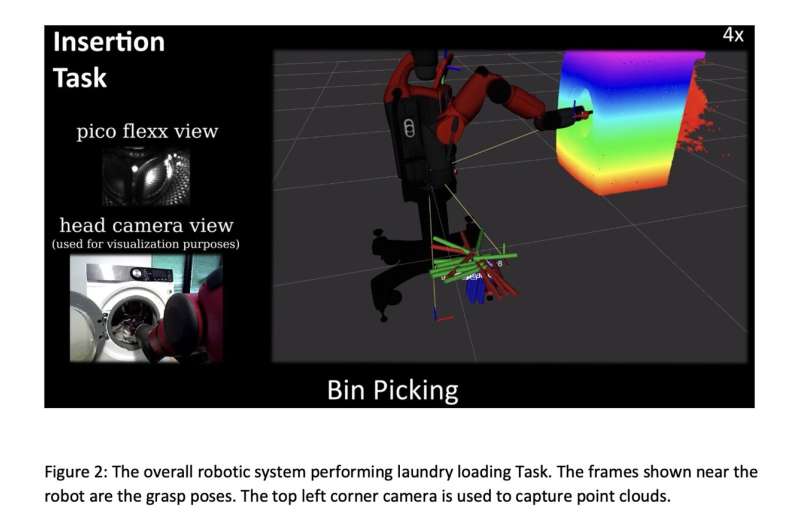

After they developed their robotic system and its various components, the researchers evaluated its effectiveness in a series of tests. In these tests, they used two robotic platforms they developed, namely the Tiago and the Baxter robots, as well as an AEG washing machine.

“Our research shows that the problem of automated laundry operation wasn’t investigated in its full scope in literature,” Palli said. “This is the first time the problem of fully robotized laundry cycle operation was investigated in all its aspects at once, including grasp success, display recognition and robotic collision avoidance during interaction. Furthermore, we were also able to develop and investigate a human-like cloth grasping strategy by targeting wrinkles and blobs that are computed from live point cloud captured with 3D Time of Flight (ToF) camera.”

In the future, the automated laundry system developed by this team of researchers could be implemented and tested in real-world settings, to evaluate its performance in real-world settings. While in initial tests the system achieved promising results, the researchers now plan to continue working on it, to improve its generalizability and its ability to handle textile items further.

“There are two proposed future research directions,” Palli added. “The first line of extension is to evaluate deep neural networks for the task of wrinkle identification grasp detection. This will allow further generalization of the previously developed vision algorithms. The second area of extension would be to fully deploy the proposed system in an industrial scenario and potentially quantify the economic and other benefits gained from this robotic system. We know that our industry partner will be conducting further work in this direction.”

#Robots; #AutomatedLaundry