A striking landmark in Vancouver, Canada, “The Big Yellow Sulfur Pile” is a testament to the massive amounts of elemental sulfur produced from the hydrodesulfurization process of petroleum refining.

In 2013, Prof. Pyun’s group from the University of Arizona developed inverse vulcanization, a method to synthesize a sulfur-rich polymer (SRP) containing elemental sulfur content of more than 50 wt% in the backbone of this new polymer. This elemental sulfur was synthesized as a chemically stable and solid-state SRP by copolymerizing it with a π-bond containing comonomer.

SRPs have usually been applied to make polymer-based infrared (IR) optics due to their intrinsically high transparency and high refractive index in the IR region, replacing expensive and fragile typical IR materials like Ge, ZnS, and ZnSe. Beyond this optical application, a research team led by Professor Jeong Jae (JJ) Wie from the Department of Organic and Nano Engineering at Hanyang University are now turning this vibrant yellow waste into a valuable resource for sustainable energy.

The paper is published in the journal Advanced Materials.

Triboelectric nanogenerator (TENG) has been considered a promising eco-friendly energy harvester that converts wasted mechanical energy into electricity. However, state-of-the-art TENGs typically use fluoropolymers that have a high potential of releasing hazardous per- and poly-fluoroalkyl substances (PFAS) into the ecosystem. Once absorbed into the human body, PFAS can remain for long periods due to their stable chemical structure and can cause serious health risks such as cancer, immune system damage, and miscarriage.

To address this critical environmental issue with TENGs, Prof. Wie’s research team has developed a new sulfur-rich polymer-based TENG. Using elemental sulfur offers three advantages in terms of economy, sustainability, and TENG output performance. Elemental sulfur is very cheap yet possesses high purity because 7 million tons of sulfur are generated annually through the gas-phase hydrodesulfurization process. Upcycling elemental sulfur offers great advantages in terms of sustainability, as elemental sulfur waste has limited uses and poses significant storage problems.

Importantly, elemental sulfur has the highest electron affinity of −200 kJ mol−1, higher than that of carbon (−122 kJ mol−1). Electron affinity is a measure of energy released when an atom gains an electron. An atom with high electron affinity favors gaining an electron and becomes more stable with a lower energy level than an atom with lower electron affinity. This means that sulfur-rich polymers can be great candidates for high-performance triboelectric materials because they facilitate surface charge generation.

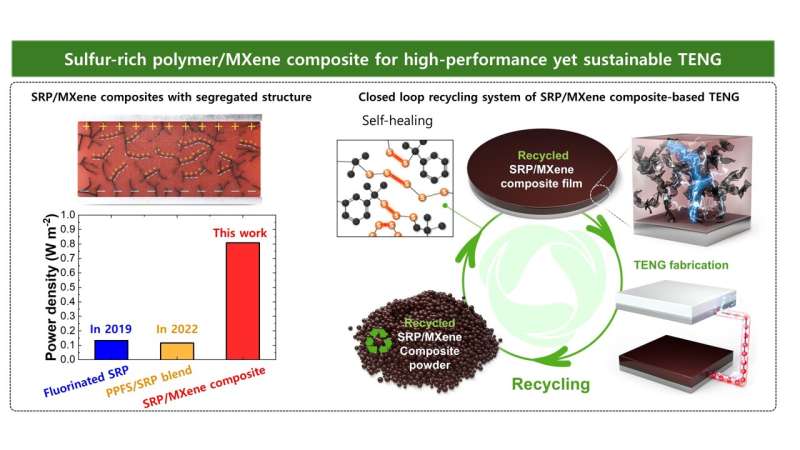

This latest development builds upon the Prof. Wie group’s previous research from 2019 and 2021 dealing with SRP-based TENGs. In 2019, the team became the first to introduce SRP-based TENG via surface fluorination of SRP film. This method achieved a 6-fold increase in voltage and a 3-fold increase in current compared to traditional PTFE-based TENGs. However, this method relied on toxic and flammable fluorine (F2) gas.

In 2021, the team developed an SRP-based blend showing surface localization of fluoropolymer via phase separation, which avoided toxic gas by using phase separation. This technique improved TENG performance without the use of toxic fluorine gas, achieving 8-fold and 9-fold increases in voltage and current outputs, respectively, over PTFE-based TENGs. Yet, despite using only 7.5 wt% of the fluoropolymer, the TENG was not entirely free from PFAS.

This research takes advancements in SRP use further without the aforementioned environmental concerns by integrating MXene, a new 2D nanomaterial, with segregated structures. Segregated structures enable SRP/MXene composite to have a uniform distribution with minimized usage of MXene under 0.5 wt% yet maximized interfacial area between MXene and SRP matrix. This structural engineering is important to enhance accumulated charges at the interface, which are essential for high TENG output performance.

Finally, SRP/MXene composite-based TENG demonstrated a record-high peak power density of 3.80 W m−2, which is 8.4-fold enhanced value than that of previously reported SRP-based TENG in 2022. This capability allows it to directly power 558-series connected blue LEDs and efficiently charge capacitors, marking a significant step toward practical applications in various fields.

Additionally, SRP/MXene composite-based TENG has exceptional recyclability due to an intrinsic self-healing property, allowing for easy recycling without performance degradation. This research not only improves TENG performance but also markedly advances true sustainability in the field. The innovative SRP/MXene composite with segregated structure sets a new standard for green energy harvesting technologies.

Journal information: Advanced Materials

Provided by Hanyang University